Conventional NDT

The methods used for conventional NDT include visual testing VT, magnetic testing MT, penetrant testing PT, ultrasonic testing UT, radiographic testing RT and eddy current testing ET, but all share common features in that the materials under test are not damage or harmed in anyway. These methods are well established, common, and widely implemented.

Visual Testing (VT)

Highly-experienced personnel meet your project requirements for close and general visual testing

Visual inspection (VT) is the most widely used NDT method . Highly-experienced personnel used their eyes to determine the quality of the products. In essence, this is still the case with visual inspection. This method involves the visual observation of the surface of a test object to evaluate the presence of surface discontinuities such as corrosion, misalignment of parts, physical damage and cracks. Visual testing can be done by looking at the test piece directly, or by using optical instruments such as magnifying glasses, mirrors, borescopes and computer-assisted viewing systems. VT can be applied to inspect castings, forgings, machined components and welds and is used in many sectors of industry.

Magnetic Particle Testing (MT)

Detects surface and near-surface cracks in ferrous material

Magnetic particle inspection (MT) is a non-destructive testing method used to detect surface and slightly subsurface flaws in ferromagnetic materials (such as carbon steel). It is used routinely to inspect welds, piping, pressure vessels and structural steel components.

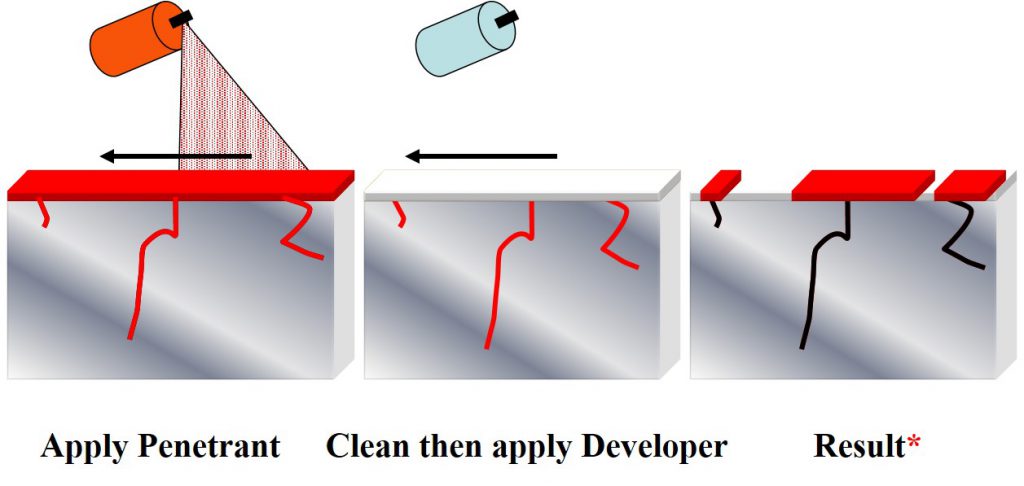

Liquid Penetrant Testing (PT)

Detects surface-breaking cracks and defects for non-ferrous / non-magnetic material

Liquid Penetrant Testing (PT) is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

Ultrasonic Testing (UT)

Ultrasonic testing is a form of nondestructive testing. Ultrasonic testing uses special equipment to send high frequency sound waves to penetrate a material's thickness. Other special equipment is then used to receive these sound waves to evaluates wall thickness and wall loss and detects internal flaws

Radiographic Testing (RT)

Radiographic Testing (RT) is a non-destructive testing (NDT) method which uses either x-rays or gamma rays to examine the internal structure of manufactured components identifying any flaws or defects. In Radiography Testing the test-part is placed between the radiation source and film (or detector)

Eddy Current Testing (ET)

Eddy Current Testing (ET) is a versatile NDT method that can be used to detect (near) surface defects in conductive materials without removing the coating. An electromagnetic inductor is used to generate a magnetic field.